With the thousands of communications satellites orbiting Earth and thousands more expected, a Tucson-based startup is focused on a better way to produce the antennas that link those satellites to users on the ground.

With the thousands of communications satellites orbiting Earth and thousands more expected, a Tucson-based startup is focused on a better way to produce the antennas that link those satellites to users on the ground.

And with a recent million-dollar federal funding award in hand, Paramium Technologies plans to start making precision reflector panels for ground-based satellite dish antennas — and for similarly constructed radio telescopes — with a production system developed by its founders at the University of Arizona.

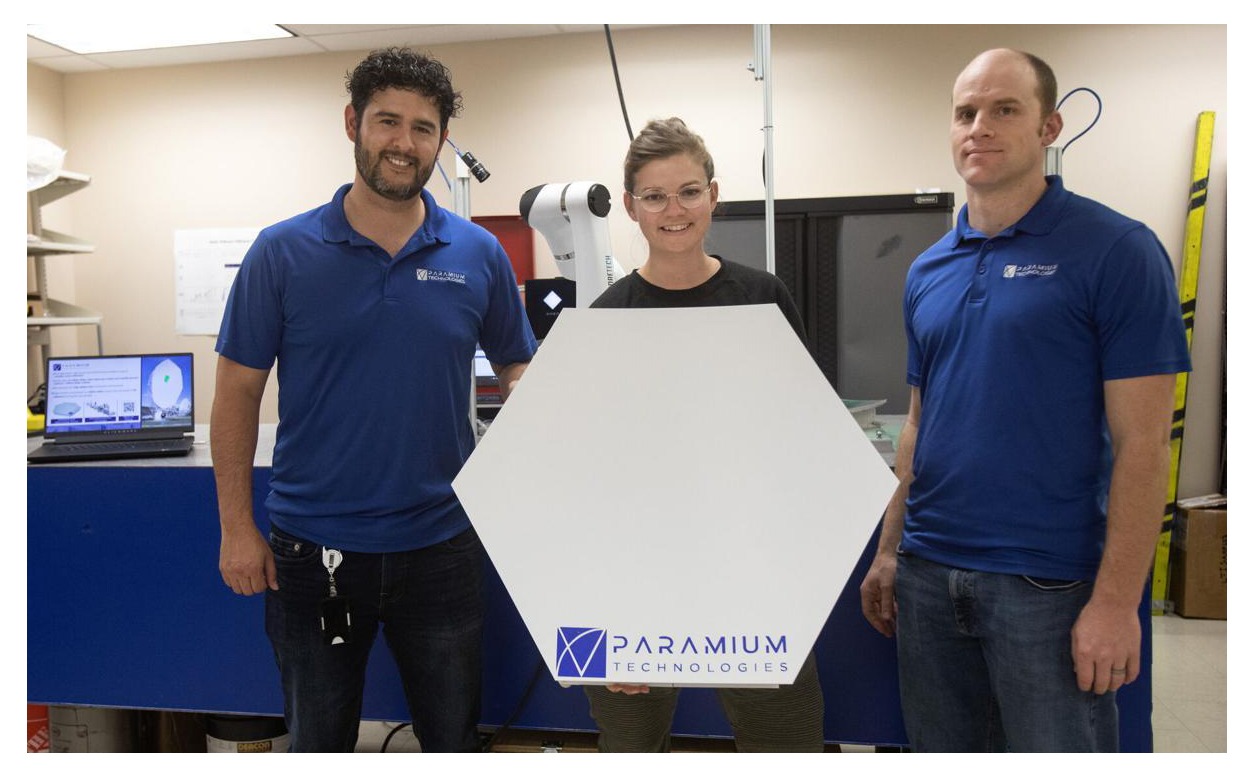

Founded by UA doctorate alumni Christian Davila and Justin Hyatt, Paramium recently was awarded a $1 million Small Business Innovation Research grant funded by the National Science Foundation to build a full-scale production line to make complex curved reflector panels that are used for large satellite ground dish antennas, as well as antennas used for radio astronomy.

Launched from UA

Paramium was co-founded in 2019 by Davila, who got his doctorate in mechanical engineering from the UA in 2020, and Hyatt, who got his Ph.D. in optical sciences from the UA’s James C. Wyant College of Optical Sciences in 2019.

The company was created with help from Tech Launch Arizona, the UA’s tech commercialization arm, which helped Davila and Hyatt file for patents, license their technologies through the school and develop business strategies.

The pair also licensed one UA technology patented by UA Regents Professor Roger Angel, who served as advisor for Davila and Hyatt during their doctorate work, who had developed a method to precisely shape multiple glass mirrors for concentrating solar generators.

In 2021, Paramium won a sponsored-launch competition to join the UA’s tech-oriented business incubator, the UA Center for Innovation. The company took up residence at the UACI at the UA Tech Park, across the park campus from the offices and labs of Steward Observatory, the UA’s astronomy research arm, where both Davila and Hyatt have worked as engineers. Hyatt, who still is senior research associate at Steward, has focused on radio astronomy — a branch of astronomy that studies non-visible radio signals from celestial objects — and radio telescope manufacturing. Davila said the company is focused on making reflector panels for satellite dish antennas and radio telescopes faster and cheaper than traditional methods.

Shaping with precision

Shaping with precision

Paramium’s technology has significant advantages for makers of a new generation of “off-axis,” or asymmetrical, reflector dishes, said Davila.

Off-axis reflector dishes place the antenna that receives the reflected signals to the edge of the reflector dish, minimizing interference from the antenna assembly that reduces performance in more traditional, axial designs, he said.

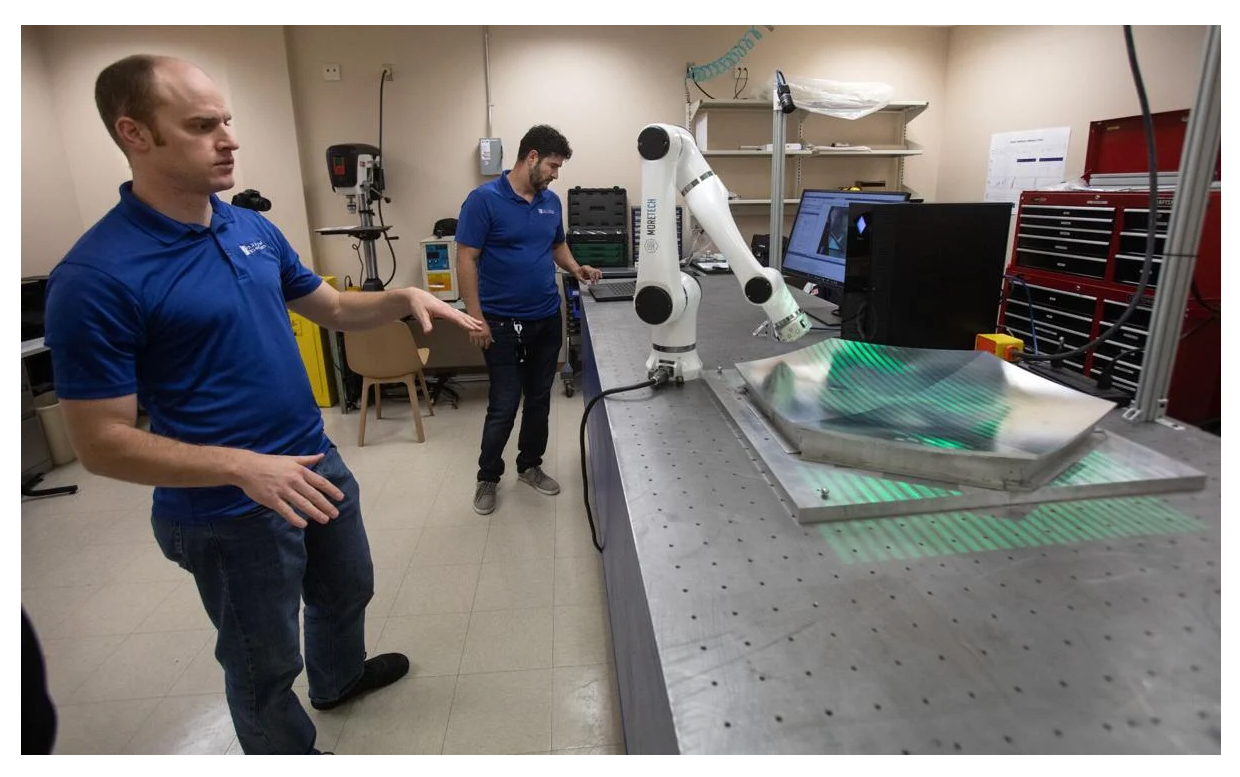

Davila said an example of off-axis dishes include the Next Generation Very Large Array, a planned array of more than 200 off-axis radio telescopes across nine states, including Arizona, as well as Puerto Rico. The array is under development by the National Radio Astronomy Observatory and industry partners, with construction planned to start in 2025. Off-axis antenna designs allow greater efficiency and data speeds, for example, but also create a challenge to create the array of computer-designed reflector plates. “In the next generation, each panel is different, because this is off-axis, so that shape is a little bit different, and that’s the thing that makes it a bit complicated to manufacture,” said Davila, who has also worked as a senior systems engineer at Roche Tissue Diagnostics at its research and manufacturing plant in Oro Valley since 2020.Paramium’s patent-pending technology works by using inductive heat and electromagnetic force to press a metal plate, typically aluminum, to an adjustable, computer-controlled mold. “We need to have a mold that gives the shape that we want, so we take a flat aluminum panel and set it on the mold and then it shapes, it conforms, to the mold,” Hyatt said.

Saving money and time

The adjustable, reusable mold is much cheaper and faster than the common method of shaping reflector panels, which involves multiple molds machined out of solid metal, he said. “Every panel in a dish could be different, so you would need to make a separate mold for each panel, which is really expensive — molds can be half a million dollars to machine one out of a block of metal,” Hyatt said.

Roslyn Norman, Paramium’s chief operating officer and a UA mechanical engineering grad, said making custom tooling for multiple panels of varying shapes also is a time-consuming process. “Lead time can be up to two years sometimes, depending on where you source your materials and what materials you need,” said Norman, who joined Paramium in 2021 as engineering manager and principal investigator on Paramium’s SBIR awards from the NSF. Hyatt said since a single, reusable mold can make all the different shapes required, there is no need for any custom tooling for manufacturing the panels. “A customer could come to us and request a free-form shape that we’ve never seen before, and we could crank out a panel in a few days,” said Hyatt. Paramium plans to use the $1 million SBIR grant to build an automated, “Industry 4.0” reflector panel production line to heat and press each panel under computer control. Paramium was awarded the $1 million SBIR grant after completing work under a $256,000 Phase I awarded by NSF in 2021 through a competitive grant process. Paramium is using optical software technology developed by Hyatt to measure the finished panels. Hyatt co-founded another company, Fringe Metrology, to commercialize that technology through Tech Launch Arizona.

Meanwhile, Paramium is looking to raise additional funding, which could be matched up to $500,000 by the NSF, to help it build out its assembly line and take the product to market.

Growing market

It’s potentially a big market for satellite antenna dishes alone.Driven by high-speed satellite communications networks, the space ground station market is expected to grow more than 7% annually and the market for reflectors alone is worth about $20 billion, according to market studies cited by Paramium. And Paramium’s production method has wider uses, Davila said. “We want to start with highest added value, which is space applications,” he said. “But we also think that there’s applications of curved panels in different industries.” Davila cited architectural uses to create panels for metal-skinned buildings, as well as aircraft fuselages and perhaps automotive parts. “We do have ambition to go and chase different industries, in a later stage,” he said. “And it may be that in some industries, we may be doing the production, (but) most likely we will be selling these machines.”

TechParksArizona.edu

TechParksArizona.edu

Apply

Apply

Stay Connected

Stay Connected

Login

Login